Source material for Vietnamese wood pellets

In Vietnam, wood pellets are typically made from waste wood such as sawdust, shavings, and tree branches. These materials are pressed under high pressure into the pellet format. Some informants shared that small- scale producers also indiscriminately used any timber available in their local area, with a network of traders who buy materials from villagers. Some large-scale producers, however, have their own plantations, typically of acacia or eucalyptus wood, some of which are FSC-certified.

Some concerns

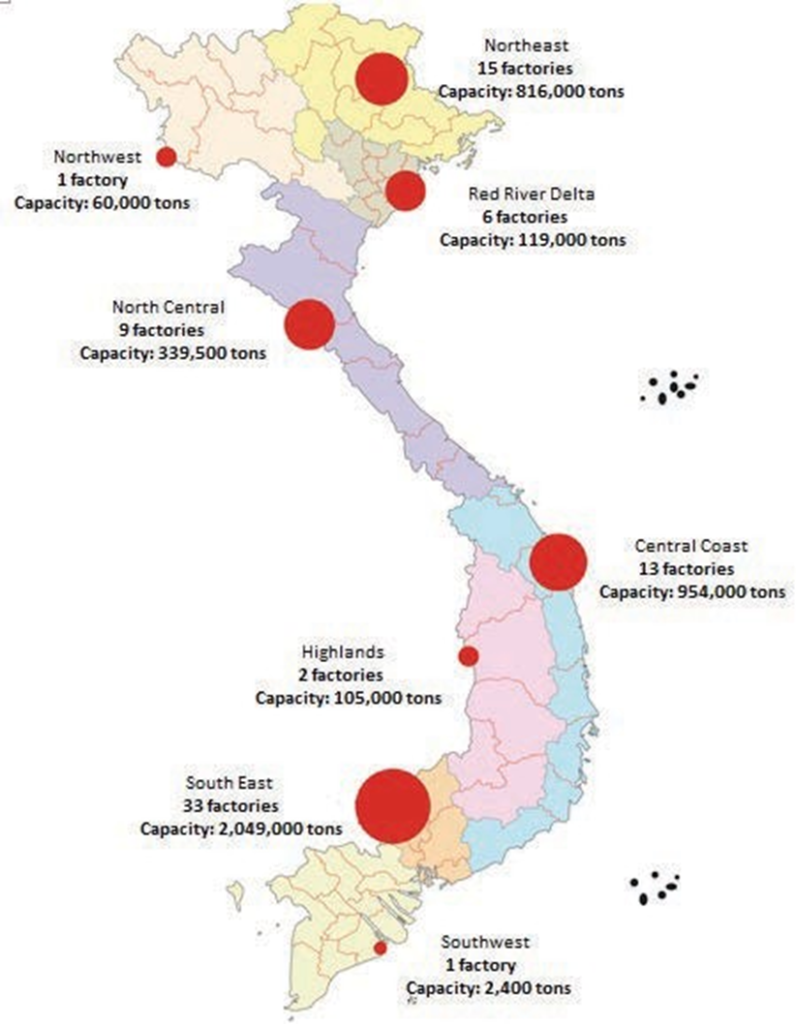

The wood pellet production and export industry in Vietnamhas undergone a great deal of development in the last decade, mainly to meet the expanding demand for bioenergy in Japan and South Korea after the 2011 Tōhoku earthquake and tsunami and resulting nuclear disaster. The demand in these countries continues to grow, stimulating export-oriented production in Vietnam.

As with any fast growing industry, concerns exist. First, sources of timber used for wood pellets have not been tightly controlled, leading to inconsistent or low product quality. This has triggered a reduction in export price. Uncontrolled timber input may also have negatively affected forest resources, if the timber is being collected from small trees and branches in the forest. There are rumors about a mixing of FSC and non-FSC certified materials in factories, but labeled as FSC certified. This information needs to be investigated in the future.

Second, though wood pellets have become one of the industry’s most important export products, their production and export has not received sufficent attention from the government. The production and export is uncordinated and lacks management and supervision.

Third, there’s little to no coordination among producers and exporters, which leads to unfair competition and rivalries among them, specifically over raw materials, export prices, and buyers. Some buyers make use of this advantage, working with invidual producers, using the price offered by a producer/exporters to bargain for lower price from other ones. Eventually, the price dropped and buyer’s benefits grew. The lack of coordination among producers and exporters is partially the result of the absence of an organization representing this sub- sector. This hampers the connection between these producers and exporters, and policymakers, for the development of the sector. Competition over raw materials takes place not only among producers but also between these producers and enterprises producing other products such as wood chips and plywood using the same materials. Competition over materials will be more severe in the future.

Finally, many wood pellet producers and exporters, especially small-scale, do not understand export markets. These enterprises do not have access to market information concerning changing demands, including the increasing number of legality, and sustainability requirements. Lack of market information not only makes these enterprises unable to build long-term business plans, but also puts them at risk of failing to meet the requirements of export market.

OVERC – Vietnam

OVERC was established in Vietnam, which has 17 FTA (Free Trade Agreement).

Vietnam is one of the countries with the most FTAs in the world.

Our main activities are manufacturing and distributing Wood Pellets, Plywood and Funiture.

Our wood source are made from plantation wood (Legal source/FSC).

Apart from that, our products have been exported to many countries around the world such as EU, Australian, Japan, Korea, etc.

OVERC Co.,Ltd would like to wish you all the best at this time.

For more information on our products, please visit our website at OVERC.VN – Renewable World.